[ad_1]

The list of brands experimenting with more sustainable new materials keeps growing.

Adidas redesigned its classic Stan Smith sneakers with mushroom-based mycelium leather; Lululemon used the same material to make yoga mats and accessories; and Stella McCartney used it to make a bag and bustier. Newlight, a startup that turns greenhouse gas emissions into carbon-negative leather, has partnered with Nike. The North Face made a limited-edition jacket from Spiber, a version of silk that’s fermented in tanks like beer.

H&M used Flwrdwn, a new down alternative made partly from wildflowers, in a children’s puffer jacket, and Vegea, a grape-based leather made from wine by-products, in shoes and bags. More than 1,000 brands have experimented with Pinatex, a type of leather made from waste from the pineapple industry. Dozens of other partnerships exist.

“It’s very much basically the material version of what’s happening in the food space,” says Elaine Siu, chief innovation officer at the Material Innovation Initiative, a nonprofit that tracks and supports the industry, which recently published a report outlining how brands are working with new material producers.

In the same way that Impossible Foods and Perfect Day are reinventing meat and dairy alternatives, a fast-growing number of startups and a handful of larger companies are working on alternatives to animal-based materials. Brands that rely on leather or silk—or first-generation alternatives made from plastic—are driven by consumer demand for more sustainable and ethical products.

So far, products made from new materials are launching at a small scale, like apple-based leather seats in a concept car, or capsule collections from a fashion brand. But what would it take for these alternatives to grow to a meaningful scale?

The first step happening now, in which textile manufacturers work closely with brands, is critical, Siu says. A company that’s developing a new material needs to understand both the specs that its customers need and how the material will fit into the entire production process, from mills and dyeing to sewing.

“They really need to take into account very early on in R&D, for instance, what kind of machinery is required,” she says. “And at what stage it goes to a factory. And do craftspeople actually know how to use it? They need to be trained up to know how to use a new material.”

A company that wants to use a new material to hit sustainability targets will also need to spend time educating its teams about the materials. “Everybody in the company needs to start to understand and have that new mindset of how to work with this shift,” Siu says. Some products may be more challenging to make with new materials than others, like a high-heeled shoe, which already requires a high level of skill to make, versus a jacket.

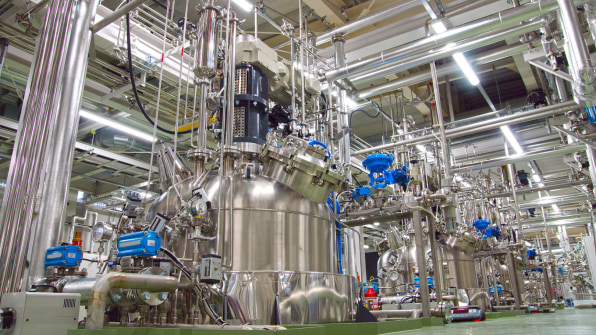

Once a new material can meet a brand’s quality and production requirements, the company making it has to work on the technical details of how to produce at a large scale. The next step is the funding to begin building large production facilities. Some fashion companies are investing directly. Adidas, as one example, bought more than $3 million worth of shares from Spinnova, a company that turns wood and clothing waste into new fabric. Allbirds invested $2 million in Natural Fiber Welding, a startup that makes plant-based leather without synthetic glues (BMW’s venture arm was another investor).

With funding in place, some companies are beginning to ramp up production. MycoWorks, a biomaterials startup that makes leather from mycelium, recently raised $125 million to build its first mass-production facility. If the field of companies in this space can begin to replace leather and other conventional materials, it could have a real impact. Animal leather has a large carbon footprint; Newlight’s emissions-based leather, on the other hand, actually has a positive impact, with a footprint of negative 87.76 kilograms of CO2 per kilogram of material produced.

[ad_2]

Source link